The Magic Of UV Bonding

Revolutionary UV Bonding: Precision and Strength in Glass and Metal Design

UV bonding is an advanced technique used to join glass to glass or glass to metal with the help of a specialised adhesive that cures and hardens when exposed to ultraviolet (UV) light.

The result is an exceptionally strong and nearly invisible bond, eliminating the need for traditional mechanical fixings.

The true magic of UV bonding lies in its precision and versatility, enabling the creation of intricate and innovative designs that were once impossible with conventional methods.

Whether for commercial or domestic purposes, UV bonding elevates both functionality and aesthetics. From crafting sophisticated retail display cabinets and unique home décor pieces to designing practical office fixtures, this technique unlocks new creative possibilities.

Additionally, UV adhesives often contain fewer volatile organic compounds (VOCs), making them a more environmentally friendly choice.

5 Key Features of UV Bonding

-

Unmatched Strength

The UV bond is often stronger than the materials it joins. -

Invisible Joints

Bonds dry crystal clear, leaving no visible glue marks for a seamless finish. -

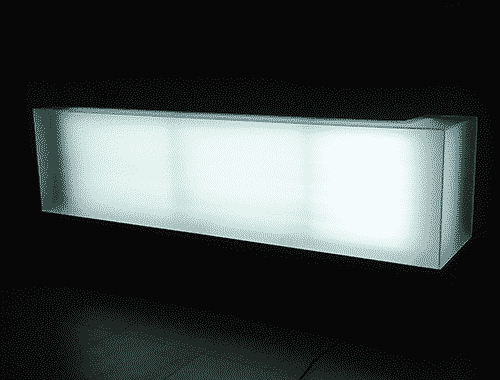

Exceptional Versatility

Frosted glass can be used to achieve even lighting without any visible dotting, perfect for artistic or functional designs. -

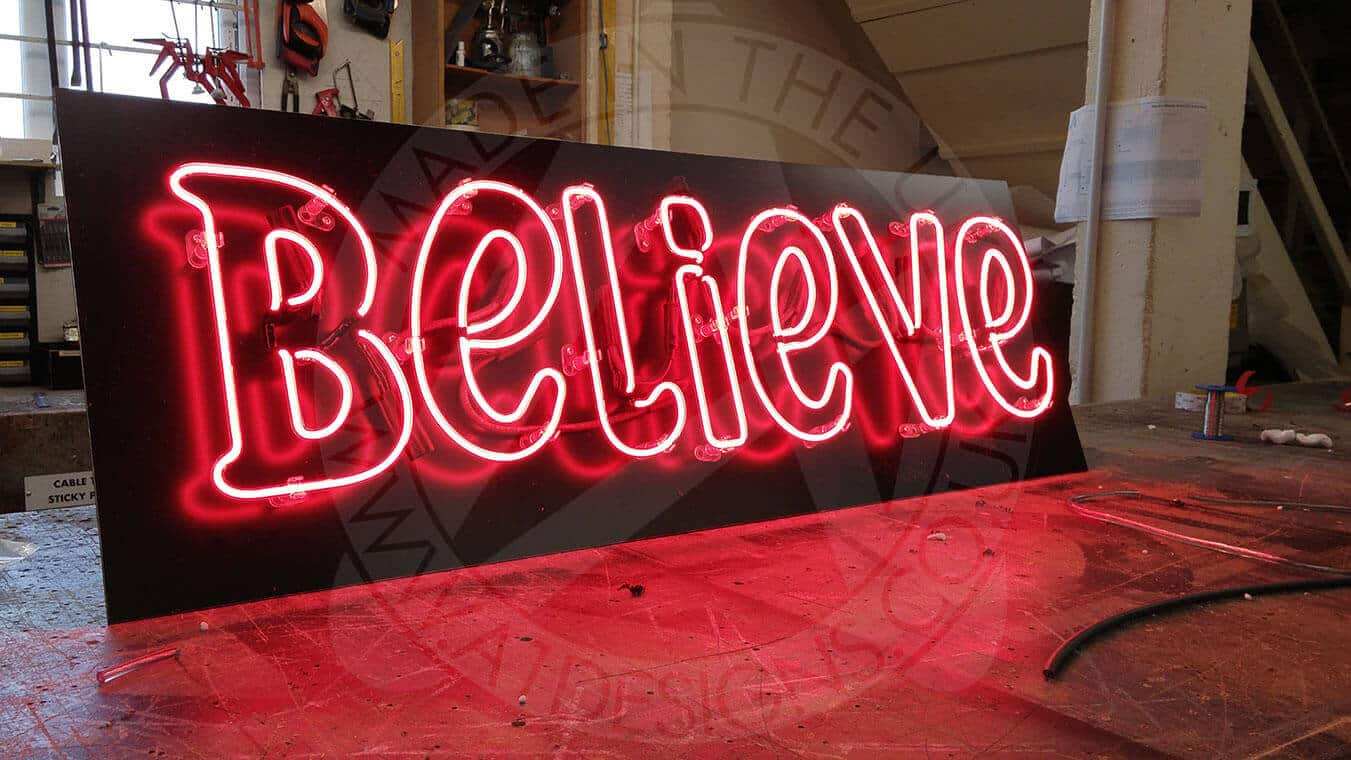

Customisation Potential

Incorporate logos or intricate designs onto glass panels using sandblasting techniques for a personalised touch. -

Minimal Heat Generation

The UV bonding process produces very little heat, making it ideal for heat-sensitive materials.

Experience a new standard of design and functionality with UV bonding—perfect for projects where precision, durability, and elegance are key.

Visit the A1deSIGNS website for more information on The Magic Of UV Bonding